Viscose vs. Modal vs. Lyocell - Difference?

You've probably heard of all three fibres. You may even be wearing a version of one now. But do you know what they are? In this article, we take a spin over the similarities and differences of viscose, modal and lyocell.

Viscose, modal and lyocell are all made from plant material

That's right, viscose, modal and lyocell are all made from plants, typically trees, but it could be soybeans, bamboo grasses, or even cotton plants. They are all variations of the same fibre generically known as viscose in Europe and rayon in North America. Scientifically they are described as regenerated cellulosic fibres. That means they are composed of cellulose (a compound which gives plants their stiffness) that has been extracted, dissolved and then realigned to make a fibre. So, despite being man-made, the fibre itself is composed of long chains of cellulose molecules that have been lined up to make a useful filament (very long continuous fibre), not unlike silk. This plant-based chemical structure is what gives these textiles their desirable properties, such as a natural next-to-skin softness, breathability and good moisture management.

OK, so viscose, modal and lyocell are all plant-based. So how are they different?

The differences between viscose, modal and lyocell are subtle. It comes down to the manufacturing process and structure of the filament. Viscose and modal are made using a very similar process with similar chemicals used at each stage of production. Viscose production has been continuously refined over the past 100 years to make a textile which is soft yet easy-care. However, modal fibres are treated slightly differently after spinning to make the filaments stronger. For example, the fibres are also stretched to increase molecular alignment. This means that modal fibres have the potential to be lighter and finer and can be tumble dried without damage. Other than that viscose and modal are similar products. Lyocell is still the same plant-based fibre as viscose and modal, but it is made using a slightly different process. Lyocell production uses a different solvent to extract the cellulose from the wood: sodium hydroxide (caustic soda) is replaced by a non-toxic organic compound with the catchy name N-Methylmorpholine N-oxide (NMMO for short). This organic solvent is easier to filter and re-use in a closed loop, which is better for the environment. The Austrian firm Lenzing go a step further by only making their lyocell, branded as Tencel®, from fast-growing Eucalyptus trees from sustainably managed forests.

Eucalyptus tree

The end product of Lyocell is still plant-based, just like viscose and modal, with the same natural feel and desirable properties. As well as this, a byproduct of the different production method is that the internal structure of the fibre is more uniform which further improves its ability to absorb water.

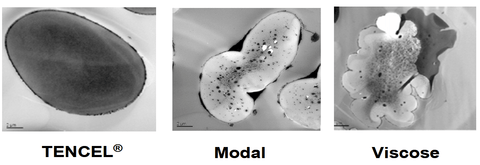

In the image below the internal structures of Tencel® (lyocell), modal and viscose are seen under an electron scanning microscope. The dark areas are where water has been absorbed into the micro-pores of the fibres: you can see clearly that the absorption of the water in Tencel® is more uniform. This internal structure is a product of the different manufacturing process and gives fabrics made from Tencel® improved moisture absorbency and breathability.

Cellulose-based fibres under an electron scanning microscope. Dark areas show water absorbed into the structure of the fibre. Picture Lenzing Fibres

So they are all fairly similar then? Yes. Viscose, modal and lyocell are very similar – so much so that you might be forgiven for calling them all viscose. The important thing to remember is that they may be man-made but they are not synthetic. In fact, as fibres that are man-made from a natural product, we might call them semi-synthetic fabrics.